As a leading belt conveyor roller manufacturer in China, SKE Industries offers a comprehensive range of conveyor rollers designed for bulk material handling belt conveyor. Our portfolio includes steel conveyor rollers, impact rollers, HDPE rollers, UHMWPE rollers and more. Our conveyor belt rollers can meet international standards such as ISO, DIN, JIS, SANS, CEMA and more.

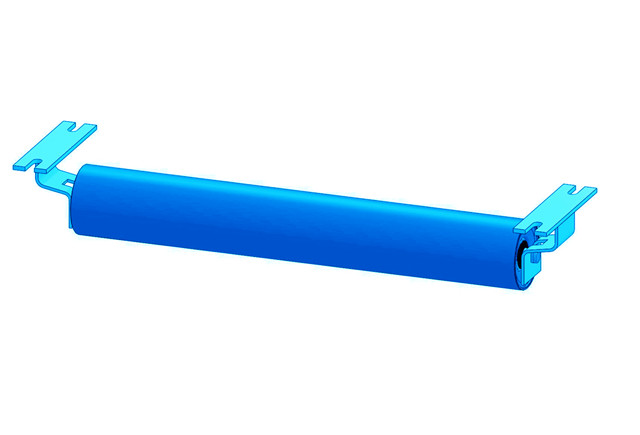

HDPE roller is made by modern polymer and fiber materials. HDPE Rollers have features of low-noise, wear resistance, and light weight. HDPE rollers can be manufactured to custom specifications.

Heavy duty steel conveyor rollers are mainly used in industries of mining, quarrying, metallurgy, cement, power, etc. We can provide steel and stainless-steel conveyor rollers.

Our impact rollers are designed with rubber rings which can absorb impact forces minimizing belt damage. Our impact roller is used in impact area, often the loading point of conveyor belt.

This steel spiral return rollers are also called self-cleaning rollers and they can clean the sticky materials on the conveyor belts. The steel spiral return roller is used as support for the return side of belt.

The rubber disc return rollers are similar to impact rollers. They are covered with rubber rings too. SKE rubber disc return rollers can assist to remove carryback of belt.

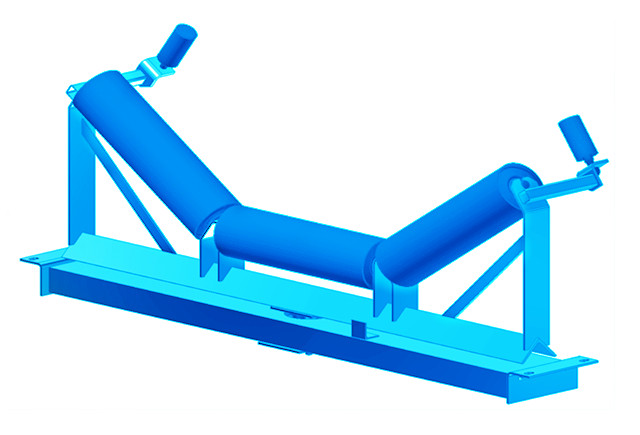

The friction self-align conveyor rollers can prevent conveyor belt deviation. They can keep conveyor belts running smoothly. It is a special roller mainly used for conveyor belt alignment.

The Tapered Conveyor Roller is widely used in steel mills, power plants, docks and coal mines, etc. It works as self-align rollers. It is produced with conical steel pipe.

The Roller Bracket is a necessary part of belt conveyor machine. All the rollers will be installed on the roller brackets. We provide toughed, flat, and V shaped roller brackets for sale.

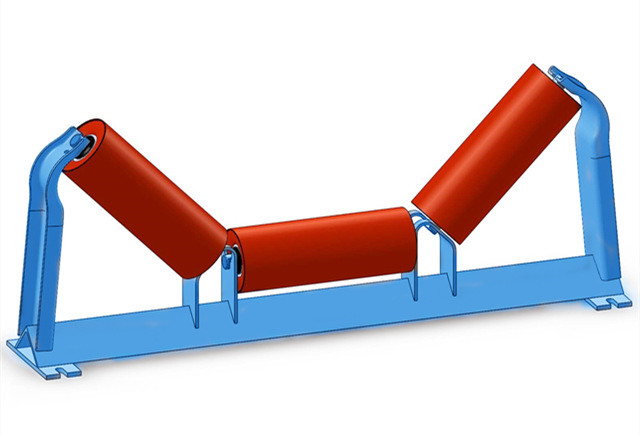

Troughing rollers are the most common belt conveyor rollers used on the carry side. SKE troughing idlers come in 20°, 35°, and 45°. The troughed rollers can be carrying rollers and return rollers.

Belt conveyor carrying rollers are used to carry conveyor belt and support bulk materials on conveyor belt working surface. The carrying conveyor rollers can be troughed and flat.

Belt conveyors return rollers are used to support the belt as it cycles around to be loaded again. we provide flat return rollers, rubber disc return rollers, self-aligning training return rollers and v return rollers.

Strategically placing belt training rollers along the conveyor keep the belt running. We provide belt carry and return training rollers. The training roller often consists of three normal roller and two guide rollers.

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

| Conveyor Idler Roller Standard | CEMA(CEMA B, C, D, E, F), DIN, ISO, GB, AS, GOST, SANS, etc. |

| Optimized Idler Roller Bearings |

|

| Conveyor Roller Bearing Brands | SKF, FAG, NSK, LYC, HRB, or ZWZ |

| Roll Shell Materials | The roller shell is the cylindrical part of the idler that comes into direct contact with the conveyor belt.

|

| Conveyor Idler Roller Sealing | Seals are often incorporated to protect the bearings from contaminants such as dust, dirt, and moisture.

|

| Conveyor Roller Frame Types | The frame or bracket provides structural support to the conveyor idler roller assembly.

|

We use only the highest quality materials in the manufacturing of our belt conveyor rollers.Our rollers are constructed to provide maximum strength and stability.

Our belt conveyor rollers are engineered for smooth and efficient operation. Our rollers are designed to evenly distribute the load across the conveyor belt.

We understand that each material handling operation has unique needs. In addition to standard rollers, we offer specialized rollers designed for specific applications, such as impact rollers for high-impact areas, guide rollers for belt alignment, and return rollers for the return side of the belt.

Our team of experienced engineers and material handling experts is available to provide you with expert guidance and support. We offer comprehensive installation and maintenance services to ensure that your belt conveyor rollers are installed correctly and maintained properly.

While our belt conveyor rollers are of premium quality, we offer competitive pricing to ensure you get the best value for your investment. The durability and reliability of our rollers mean fewer replacements and less downtime.