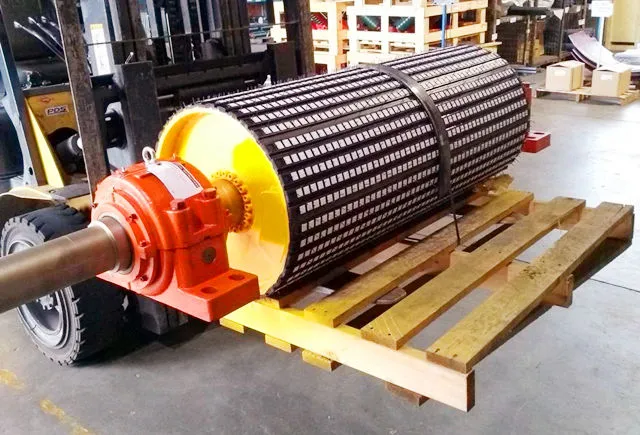

A conveyor drive pulley, also known as a head or drive drum, is a key component of a belt conveyor drive system. The drive pulley is connected to the motor, usually through a gearbox, and provides the necessary torque to move the conveyor belt. We offer conveyor drive pulleys or complete drive system.

The conveyor drive pulley is typically located at the discharge end of the conveyor system, opposite the tail pulley. The primary function of the drive pulley is to transmit power from the motor to the conveyor belt, causing it to move and transport materials along the conveyor. It can be used in many industries such as:

The motor, often connected to our drive pulley through a gearbox, provides the necessary power to drive the conveyor belt. The drive pulley transforms this power into rotational motion, moving the belt.

Conveyor drive pulleys are usually constructed from steel. The outer surface of the pulley, where the conveyor belt makes contact, may be lagged with rubber or other materials to provide better traction and reduce wear.

The design of the shaft on which the drive pulley is mounted is important. It must be robust enough to handle the loads and forces exerted by the conveyor system.

Some conveyor drive pulleys may include torque limiting devices to protect the system from overloads. These devices can prevent damage to the motor and gearbox by limiting the torque transmitted to the conveyor belt.

Safety guarding is essential for drive pulleys to prevent accidental contact with moving parts. Guards should be installed to protect personnel from potential hazards.

| Belt Conveyor Drive Pulley | |

| Belt Width | 500-2800mm (19-110.2 inch) |

| Pulley Length | 500-3200mm (19-125.9 inch) |

| Diameter | 200-1800mm (7.8-70.8 inch) |

| Standard | ISO9001:2008, CEMA, DIN, TUV, JIS, AS/NS, etc. |

| Working Life | More than 30,000 hours. |

| Surface | Flat Rubber Lagged, Ceramic Lagged, Diamond Rubber Lagged, etc. |

| Main Material | Carbon Steel Shell |

| Length of conveyor drive pulley depends on the width of conveyor Belt. You can get drive pulleys with hot & cold vulcanized rubber lagging, plain or grooved, as required by client. | |

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

When you leave a message on this website, please provide your country name or phone number including the country code. If you have WhatsApp Number, please show us too. This way we can get in touch with you faster.