Bucket elevators, also known as grain legs, are critical components for the efficient vertical transport of bulk materials across a variety of industries. SKE is bucket elevators manufacturer in China, and offer belt bucket elevators and chain bucket elevators, designed for industries like mining, agriculture, and ports. With lifting capacities up to 1541 m³/h and heights reaching 80m, our solutions ensure reliable vertical material transport.

The GTD belt bucket elevator uses EP/NN belt or steel cord belt to lift the buckets. The lifting efficiency can reach 788m³/h. The lifting height can reach up to 80m (100, when using steel cord belt).

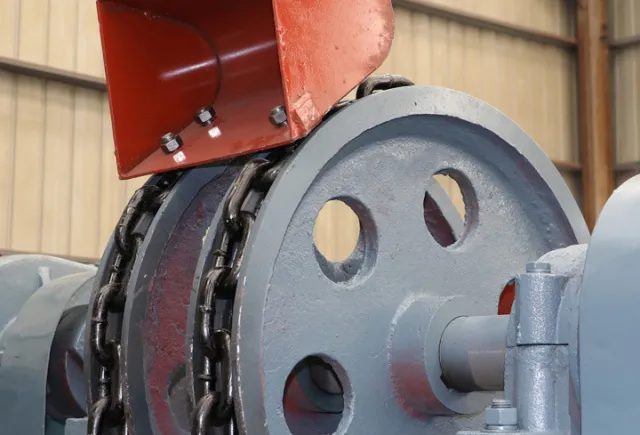

GTH round link chain bucket elevator uses round chain to lift the buckets, and the chain is made of high-strength alloy steel. The lifting efficiency can reach 1541m³/h. The lifting height can reach up to 80m.

NE plate chain bucket elevator uses plate chain to lift the bucket, and the chain is made of high-strength alloy steel high-strength plate. The lifting efficiency can reach 800m³/h. The lifting height can reach up to 40m.

|

Bucket Reclaiming Method |

|

| Method | Materials |

| Scoop for Reclaiming | powdery and small bulk materials with less abrasiveness |

| Inflow for Reclaiming | bulky and abrasive materials |

We provide centrifugal discharging elevator, positive discharging elevator, and continuous discharging elevator.

|

Bucket Elevator Discharging Method |

|

| Method | Materials |

| Centrifugal Discharge Bucket Elevator | powdery, granular and small block materials that are easy to flow |

| Gravity Discharging | bulky and abrasive materials |

| Centrifugal + Gravity (mixed) | poor fluidity and wet materials |

60000

Factory (㎡)

100+

Workers

20+

R&D Engineers

20+

Welders Certified

160+

Marketing Areas

1000+

Projects

The bucket on the bucket elevator is usually made of durable materials such as steel or plastic, and is designed to scoop up materials as the bucket elevator conveyor moves upward. The bucket then unloads the materials to the top of the elevator, where they can be directed into storage bins or other processing equipment, such as belt conveyor. It can be widely used for vertical transportation of bulk materials in:

Bucket elevators are used for vertically transporting bulk materials, such as grains, minerals, and industrial products.

When it is used in grain handling, it is installed beside a grain silo. In grain handling industries, some engineers often call it grain leg.

A bucket elevator conveyor works by using a series of buckets attached to a belt or chain to carry materials from one level to another.

The main types of bucket elevators are centrifugal discharge, continuous discharge, and positive discharge elevators.

Bucket elevators can transport a wide range of materials, including grains, seeds, coal, ores, and processed foods.

Maintenance involves regular inspections, lubrication of moving parts, and timely replacement of worn-out components.

Safety measures include following established protocols, providing emergency stops, and ensuring the use of personal protective equipment.